Edge and IoT applications for rail vehicles

WE EXPLOIT THE POTENTIAL OF YOUR DATA

THE CHALLENGE:

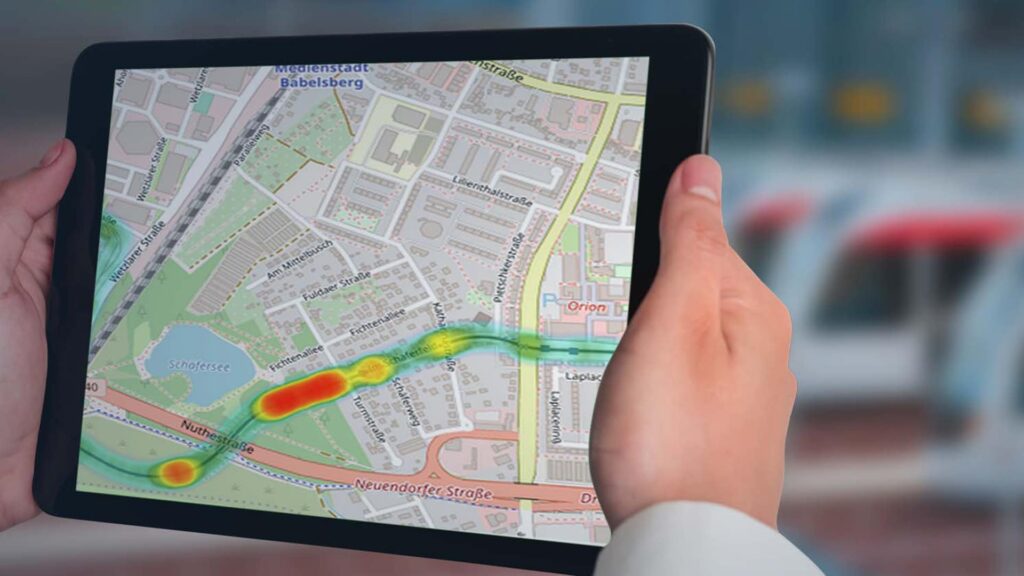

Communication-capable connected components and systems are a valuable potential source of data in rail transportation. Until now, they’ve often remained just that: a potential source. How can data be preprocessed, aggregated via interfaces, intelligently analyzed, and visualized so that it’s optimally informative?

WHAT GIVES YOU ADDED VALUE:

We turn vehicle and infrastructure data into knowledge that enables reliable decision-making and strategic planning – including eliminating frequent causes of accidents in mass transit; monitoring the status of typical vulnerabilities like doors in commuter and mainline transportation; intelligent networking between track and train in order to maximize reliability and punctuality; and the implementation of new, usage-based business models.

WHAT WE DO DIFFERENTLY:

We design and implement the entire data architecture, from the component interface and preprocessing on the vehicle (edge processing) to analytics using an IoT platform and ultimately to a dashboard that’s designed to support decision-making – all as a worry-free service that embodies a profound understanding of the application.

REFERENCES

WHAT OUR USERS ARE SAYING

Codewerk is a valuable partner for application development and system development. We especially appreciate that we’re dealing with experts who understand our core business beyond the software and also consider the application.

Hans Halbmeyer | Head of Development Siemens Mobility GmbH

Model-based software engineering for the vehicle control unit

GETTING THERE FASTER

We speed up the development and validation of vehicle control software using model-based software engineering.

DEVELOPMENT OF IOT AND EDGE APPLICATIONS

FOR SMART RAIL OPERATIONS

By monitoring “health states,” identifying optimization potentials in the network, and enabling predictive maintenance, our application development transforms your data into knowledge.

Subsystem integration for the vehicle control unit and operator network

SO IT ALL WORKS TOGETHER

When subsystem integration is performed for the vehicle control unit and operator network, we take full responsibility for combining multivendor architectures to form a functioning whole.

Innovations

WE’RE SHAPING THE FUTURE

We play an active role in both national and international research projects that are working to prepare rail vehicle technology for the challenges of future decades.

Development of a basic system

BASIS FOR THE FUTURE

By participating in international standardization projects, we’re contributing to the creation of a highly expandable and modular basic system of the future.

Device integration for SIMATIC PCS 7 / SIMATIC PCS neo

YOUR COMPONENTS IN A LEADING POSITION

Siemens’ SIMATIC PCS 7 and SIMATIC PCS neo control systems are leaders in the process industry. We take responsibility for a seamless, system-compliant integration of your products or third-party components.

PROFINET Stack Integration

WE HELP YOU MAKE IT TO THE BIG LEAGUES

You want to integrate PROFINET into your chips or devices – we handle the modification of the relevant stacks as part of a carefree package for you – right up to certification.

System integration for industrial communication

SO THAT NO DATA-POINT IS LOST

Whether it’s PROFINET, OPC UA, MQTT, or applications based on them, we take on the complete integration of products for industrial communication into your system environment.

Development of IoT and edge applications

DATA BECOMES THE BASIS FOR DECISION-MAKING

You want to turn big data into smart data. We’ll build your application – from data acquisition (connectivity) and data transmission to data evaluation and utilization.

IO-LINK LIBRARY FOR SIMATIC PCS 7/SIMATIC PCS NEO

Secure point-to-point connections in industry are relatively easy to implement with the right IO-Links. We offer you the right driver so that integration is in full compliance with the system.

TURCK Remote IO FOR SIMATIC PCS 7

The system-compliant connection of TURCK systems to the SIMATIC PCS 7 process control system doesn’t have to be time-consuming. Our function block library ensures maximum convenience at the user end.

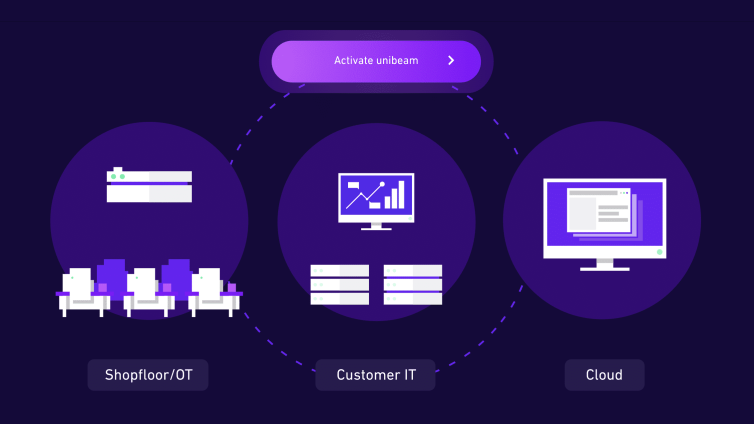

unibeam. - And suddenly it's all Smart Factory.

Do you want to experience a new generation of IIoT-platforms? Discover unibeam: an amazingly simple and efficient software to help SMEs unfold their whole potential of digitalisation.