Implementing the Digital Product Passport at Michael Koch GmbH

Digital Product Passport –

Standardized Product Information Included

Standardized Product Information Included

The challenge:

Michael Koch GmbH, a leading manufacturer of brake resistors and active energy management devices, have set their goal of giving customers seamless access to all relevant device data in the event of service or replacement.

The “digital nameplate” was to be implemented uniformly across all devices—both the custom-built energy management devices and the various models of passive brae resistors.

Another key requirement was to make the system future-proof and easily scalable to lay the foundation for upcoming industrial standards.

The solution:

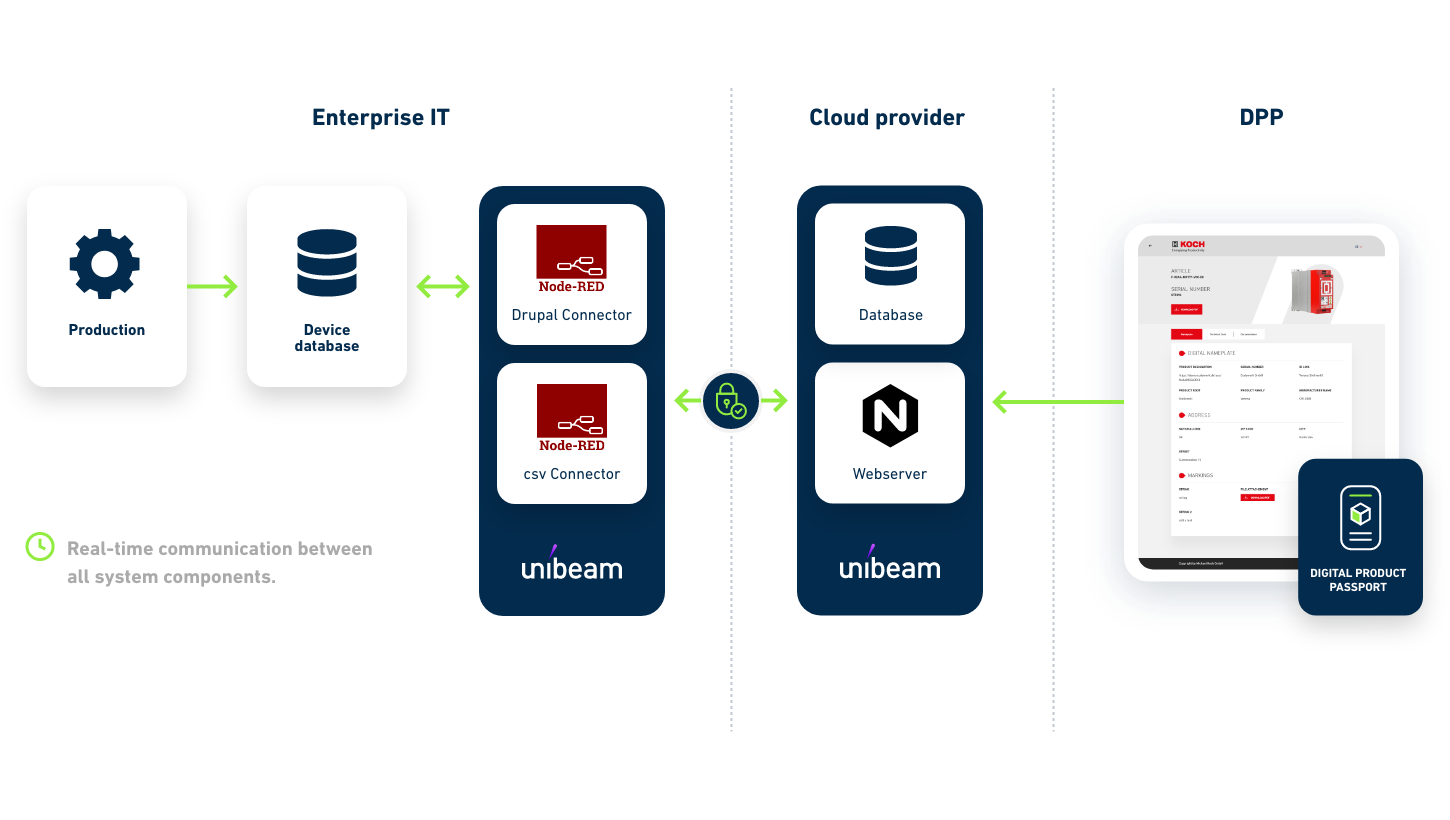

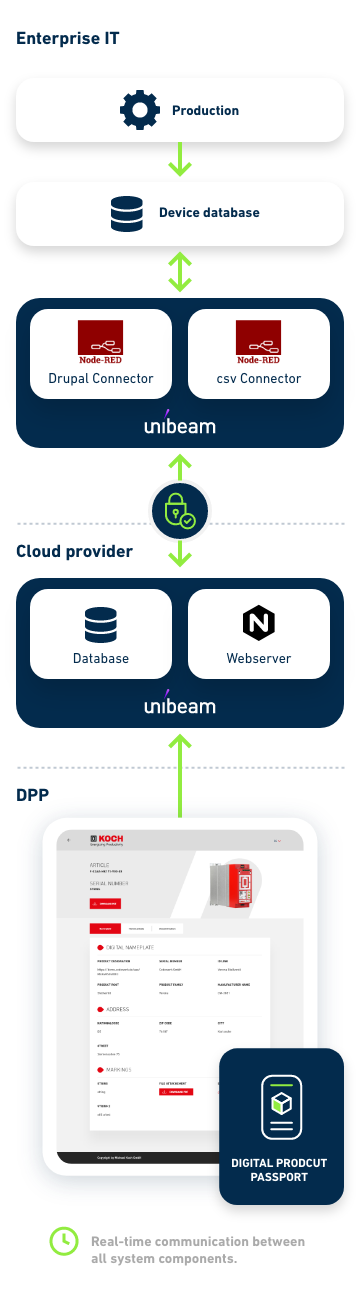

Together, we developed a customized solution based on the unibeam platform:

1. Industrial standards as the foundation

Integration of IEC 61406 ID Links and the use of Asset Administration Shell (AAS) submodels as the technological foundation for DPP4.0.

2. Scalable architecture

The system can be expanded seamlessly by the customer – by adding new properties or integrating entirely new device variants.

3. Comprehensive implementation

Precise configuration of Unistations, Node-RED flows, and web servers, all with thorough documentation.

4. Future readiness and competitive advantage

Prepared for the Industrial Data Space through standardized ID Links and readiness for the AAS Type 2 API.

The codewerk factor:

Michael Koch GmbH contributed deep product knowledge and a strong understanding of customer needs. Codewerk complemented this with technological expertise in OT/IT integration, proficiency in industrial standards (AAS, DPP), and active participation in the development of new technologies—for example, as a member of IDTA and contributor to the Factory-X research project.

By combining our competencies with the unibeam platform, we created not just a powerful solution but a successful partnership model: each party contributed its specific expertise—from initial concept through to final validation—ensuring an optimal project outcome that met all quality criteria.

Smooth commissioning and updates

Lower Engineering Costs

Time for core business

Quick help, even when things get stuck

Safe for the future with regular updates.

Quote:

With the digital nameplate on our products, we provide customers with all relevant information at a glance. Codewerk implemented all our requirements perfectly. By using modern standards like the Asset Administration Shell and the ID Link, we are ready for the future.

Fabian Hofmann, Managing Director,

Michael Koch GmbH

More about the digital product passport and co

DIGITAL PRODUCT PASS and ASSET ADMINISTRATION SHELL – The future of digital product information.

UNIBEAM – And suddenly everything is Smart Factory. Exploiting the full potential of digitalization.