Device integration for SIMATIC PCS 7 and SIMATIC PCS neo

AT A GLANCE:

The integration of your products in SIMATIC process control systems requires special expertise.

Minimize your risks with our customized solutions for system-compliant integration.

As a long-time Siemens partner and SIMATIC insider, we guarantee the necessary quality standards and processes.Als langjähriger Siemens-Partner und SIMATIC-Insider gewährleisten wir die erforderlichen Qualitätsstandards und Prozesse.

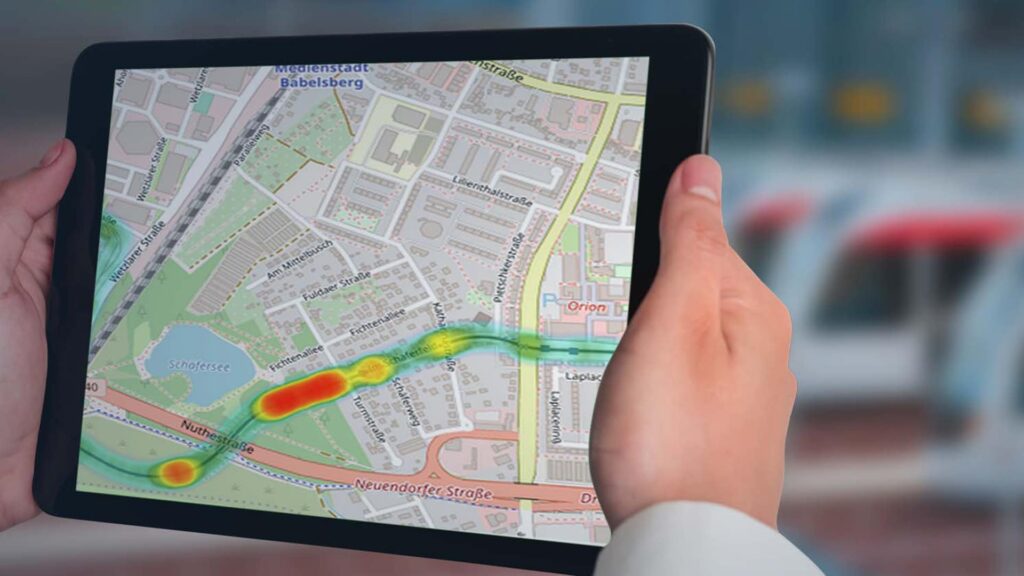

The integration of devices into SIMATIC PCS 7 and SIMATIC PCS neo is the key to exploiting the full potential of modern process control systems. Seamless integration lays the foundation for end-to-end automation of your plants.

This allows controllers, sensors, and actuators to be efficiently integrated into the process control system, resulting in a noticeable optimization of your processes. The advantages are obvious: higher productivity, improved quality, and a significant increase in efficiency. With its SIMATIC products, Siemens offers a broad portfolio that provides tailor-made solutions for a wide range of requirements and industries. This makes integration a real competitive advantage for your company and your customers.

WHAT MOVES YOU:

In the process industry, thousands of highly specialized components often have to be integrated into the control system to ensure trouble-free and cost-efficient production. Whether you are a component manufacturer or a system integrator, how can you achieve this goal quickly, risk-free, and at reduced engineering costs? We offer comprehensive support at any time if you have questions about technical details or integration.

WHAT CREATES ADDED VALUE FOR YOU:

With Codewerk, you are choosing secure, system-compliant component integration into the leading SIMATIC PCS 7 and SIMATIC PCS neo process control systems. We take care of the devices that are not natively supported by the control systems. Depending on your project and company structure, you can choose between individual order development, a partnership model, or ready-made products from our portfolio.

You can choose between different cooperation models. On request, we can also take over maintenance and customer support for the solution throughout its entire life cycle. Our comprehensive range of services extends from technical support to customized solutions.

WHAT MAKES US DIFFERENT:

As a long-standing partner of Siemens AG, we are familiar with the necessary quality standards and processes down to the last detail – confirmed by the official listing of numerous SIMATIC add-ons. With this background experience, we also create future-proof and system-compliant solutions that work for you.

BENEFITS FOR YOU AND YOUR CUSTOMERS

SEAMLESS COMMISSIONING AND UPDATES

Thanks to system-compliant solutions and updates

MAXIMUM CUSTOMER SATISFACTION

Thanks to a solution that supports all device functions and is based on proven components

REDUCED ENGINEERING COSTS

Efficient engineering thanks to system-compliant workflows

FAST HELP, INCLUDING WHEN IT’S URGENT

Thanks to our direct line to the SIMATIC team.

TIME FOR CORE BUSINESS

At your request, we’ll take over maintenance and support

FUTURE-PROOF SECURITY

Thanks to regular updates

Cooperative partnership development

We work closely with you as the device manufacturer to design and develop a solution. Following joint acceptance testing, we market the library as a product. We take charge of customer support, regular updates, and any necessary modifications. You share in the initial development costs and in ongoing maintenance costs.

Your benefits: You can offer your customers a professional integration solution at an affordable price. We do the rest.

Our “Turck Remote IO for SIMATIC PCS 7” library was created in this type of collaboration with Turck. It integrates the excom and BL20 remote I/O systems into SIMATIC PCS 7 in full compliance with the system.

Codewerk products

For devices with a high repetition factor, we offer our own products for integration.

One example is our IO-Link-library for SIMATIC PCS 7, which you can also obtain as an official PCS 7 add-on.

Our expert look forward to hearing from you.

Contact us – there’s no obligation!

Peter Hensel

+49 721 9841 4678

sales@codewerk.de

Our vision

We align our business models with the individual needs of our customers. We stand by you as a flexible partner.

Peter Hensel,

Head of Industry Solutions

PORTFOLIO

PERFORMANCE MEETS DEMAND -

DISCOVER WHAT WE CAN DO FOR YOU

DISCOVER WHAT WE CAN DO FOR YOU

Model-based software engineering for the vehicle control unit

GETTING THERE FASTER

We speed up the development and validation of vehicle control software using model-based software engineering.

DEVELOPMENT OF IOT AND EDGE APPLICATIONS

FOR SMART RAIL OPERATIONS

By monitoring “health states,” identifying optimization potentials in the network, and enabling predictive maintenance, our application development transforms your data into knowledge.

Subsystem integration for the vehicle control unit and operator network

SO IT ALL WORKS TOGETHER

When subsystem integration is performed for the vehicle control unit and operator network, we take full responsibility for combining multivendor architectures to form a functioning whole.

Innovations

WE’RE SHAPING THE FUTURE

We play an active role in both national and international research projects that are working to prepare rail vehicle technology for the challenges of future decades.

Development of a basic system

BASIS FOR THE FUTURE

By participating in international standardization projects, we’re contributing to the creation of a highly expandable and modular basic system of the future.

Device integration for SIMATIC PCS 7 / SIMATIC PCS neo

YOUR COMPONENTS IN A LEADING POSITION

Siemens’ SIMATIC PCS 7 and SIMATIC PCS neo control systems are leaders in the process industry. We take responsibility for a seamless, system-compliant integration of your products or third-party components.

PROFINET Stack Integration

WE HELP YOU MAKE IT TO THE BIG LEAGUES

You want to integrate PROFINET into your chips or devices – we handle the modification of the relevant stacks as part of a carefree package for you – right up to certification.

System integration for industrial communication

SO THAT NO DATA-POINT IS LOST

Whether it’s PROFINET, OPC UA, MQTT, or applications based on them, we take on the complete integration of products for industrial communication into your system environment.

Development of IoT and edge applications

DATA BECOMES THE BASIS FOR DECISION-MAKING

You want to turn big data into smart data. We’ll build your application – from data acquisition (connectivity) and data transmission to data evaluation and utilization.

IO-LINK LIBRARY FOR SIMATIC PCS 7/SIMATIC PCS NEO

Secure point-to-point connections in industry are relatively easy to implement with the right IO-Links. We offer you the right driver so that integration is in full compliance with the system.

TURCK Remote IO FOR SIMATIC PCS 7

The system-compliant connection of TURCK systems to the SIMATIC PCS 7 process control system doesn’t have to be time-consuming. Our function block library ensures maximum convenience at the user end.

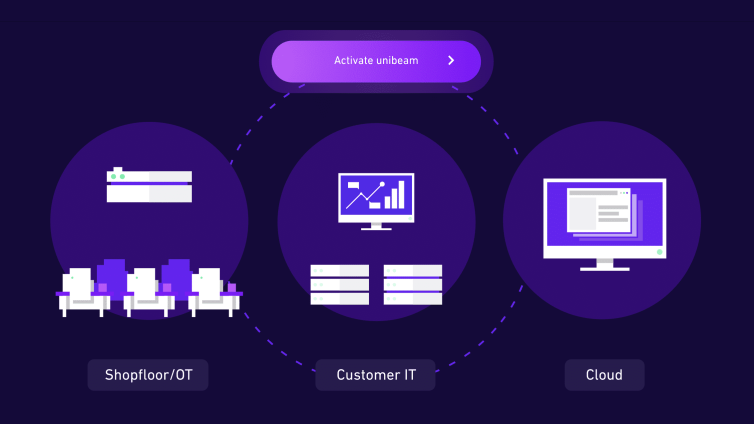

unibeam. - And suddenly it's all Smart Factory.

Do you want to experience a new generation of IIoT-platforms? Discover unibeam: an amazingly simple and efficient software to help SMEs unfold their whole potential of digitalisation.

REFERENCES

OUR SOFTWARE DEVELOPMENTS –

SELECTED EXAMPLES

SELECTED EXAMPLES

We’ll be happy to provide you with insights into other projects any time. Just contact us!

Frequently asked questions about SIMATIC PCS 7 and SIMATIC PCS neo

What does SIMATIC do?

SIMATIC is the automation brand of Siemens and stands for "Siemens Automation and Control." SIMATIC comprises a wide range of products and systems for industrial automation, including PLC controllers, industrial PCs, operator panels, and software.

What is a SIMATIC S7 controller?

SIMATIC S7 controllers form the heart of every modern automation solution.

They perform central control tasks in a wide variety of plants and processes and ensure maximum flexibility and scalability. The SIMATIC S7-1500 controller in particular stands for powerful performance and is optimally designed for demanding applications in process control technology.

Thanks to their close integration with the Totally Integrated Automation (TIA) portfolio from Siemens, SIMATIC S7 controllers can be seamlessly integrated into the SIMATIC PCS 7 and SIMATIC PCS neo process control systems. The result: optimized processes, increased productivity, and consistently high quality for your products. With SIMATIC S7 controllers, you are choosing a future-proof, powerful, and flexible control solution that can be customized to meet your specific requirements.

In which areas are SIMATIC PCS7 and PCS neo used?

SIMATIC PCS 7 and SIMATIC PCS neo impress with their versatility and are used in a wide range of industries and applications. Whether in the chemical industry, the pharmaceutical industry, food production, or other areas of the process and manufacturing industry, Siemens process control systems offer the right solution for every challenge.

An open system architecture and modular design enable flexible integration and expansion of the system.

The flexible integration of a wide variety of components and products allows processes to be customized and optimally controlled. The result: maximum efficiency, maximum productivity, and consistently high quality. With SIMATIC PCS 7 and PCS neo, you are relying on proven standards and innovative technologies that optimize your processes in the long term and make your company fit for the future.

What is SIMATIC S7-1200?

The SIMATIC S7-1200 is a compact programmable logic controller (PLC) from Siemens that is used for small to medium-sized automation tasks. It is modularly expandable, communicates via PROFINET, and is programmed with the TIA Portal. Typical applications include machine control and simple automation processes. While SIMATIC S7-1200 was developed for small to medium-sized systems with , SIMATIC S7-1500 is suitable for more complex system requirements.

What is SIMATIC S7-1500?

The SIMATIC S7-1500 is a powerful programmable logic controller (PLC) from Siemens for medium to complex automation tasks. It is the direct successor to the S7-300 series and part of the Totally Integrated Automation (TIA) Portal.

The controller is highly modular with more extensions than other series. The S7-1500 is, so to speak, the high-end PLC from Siemens and offers maximum speed and flexibility for modern Industry 4.0 applications.

What is SIMATIC IPC?

The SIMATIC IPC (Industrial PC) is a robust industrial PC from Siemens that was developed for use in industrial environments. It is mostly used for visualization, data processing, or as an edge device and runs on common operating systems such as Windows or Linux.

How can Codewerk provide support within the SIMATIC framework?

Our solutions support numerous functions, offer comprehensive visualization options, and ensure efficient communication between the individual components.

Powerful software, modern CPUs, modular assemblies, and proven PLC technology are used to ensure reliable control. Compliance with current standards and versions, maximum security, and comprehensive functionality are essential for your control system. In addition, we offer the option of individual programming and comprehensive services.