We’ll speak PROFINET for you

PROFINET IO – THE INDUSTRIAL ETHERNET STANDARD

Maximize your potential with PROFINET

PROFINET is an industry-leading, Ethernet-based fieldbus protocol that is becoming increasingly important. PROFINET enables fast and secure data exchange and high functionality in various systems and plants. PROFINET offers the latest technologies for safety, flexibility, easy integration, and diagnostics.

A PROFINET network consists of IO controllers, IO devices, and possibly an IO supervisor that can manage diagnostics and parameterization.

Meet deadlines and budget

Keeping to deadlines and budgets is crucial for the success of the project and the satisfaction of the end customer. Delays or cost overruns can jeopardize the market launch and cost trust and competitive advantages.

Precise planning and efficient implementation guarantee a smooth process, minimize risks and ensure the economic profitability of the project.

Ensure know-how

We support both chip manufacturers and device manufacturers with expert knowledge in design, integration, test , and certification. In close cooperation with the relevant manufacturers, we ensure that the functionality and safety of PROFINET systems are always guaranteed during integration and certification. Through state-of-the-art testing procedures, close cooperation with testing institutes, and targeted training, we ensure compliance with the highest standards and optimize the development process.

Create efficient production

The use of already certified components enables a faster market launch. Close coordination with chip manufacturers and compliance with PROFINET standards ensure smooth integration. This reduces development risks, optimizes production planning and guarantees on-time production with reliable PROFINET communication.

We cover all conformity classes

The various conformity classes CC-A, CC-B, CC-C, CC-D, and are essential for real-time communication and meet the requirements of a wide variety of systems and applications. The higher the class, the more powerful and time-critical the PROFINET device can be used.

As the leading industrial Ethernet standard supported by PROFIBUS & PROFINET International (PI), PROFINET is based on established IT standards such as TCP/IP, thus creating the foundation for future-proof and interoperable industrial communication.

You determine the level of cooperation

Basic Integration Suite

„Design with you“

- Consulting

- Support of

- Design & SW architecture

- Integration & implementation

- Test & certification

Collaborative Integration Suite

„Build with you“

- Working together in close exchange

- Implementation of all PROFINET relevant modules by Codewerk

- Integration into the device application by customer

Comprehensive Integration Suite

„Build for you“

- Independent implementation of all project steps perfectly tailored to customer requirements

- From first concept to successful certification

Steps of a Successful PROFINET Integration

First, we analyze all individual requirements and define the goals for integration with PROFINET. Then we select the right PROFINET products and plan the integration to create the optimal solution for your application. In the next step, the PROFINET solution is implemented, tested, and certified.

Throughout the entire process, close involvement of all parties is crucial to ensure smooth integration and sustainable networking of your systems. This makes PROFINET integration the driving force behind modern automation and the connection of OT and IT.

Concept

- Requirement analysis

- Definition of required PROFINET features

- Stack evaluation

- Definition of the software architecture

- Engineering concept

Implementation

- Stack migration to customer HW

- Stack integration into existing firmware

- Implementation of data mapping & exchange

- Implementation of GSDML file

Testing

- Stability testing

- Performance testing

- Processing all certification tests defined by PI

- SPIRTA

- NETLOAD

- Manual tests

- ART/ETS

- Profile tester

- Bug-fixing

Certification

- Organization of product certification at registered laboratory

- On-site support of certification process

Certified Product

- Handover of official certificate by PNO/PI

We find the right stack for your requirement

- reduce the complexity of the project

- minimize deadline and budget risks

- ensure future viability

PROFINET Application Profiles

PROFIsafe enables safe communication in automation networks and ensures protection against hazards caused by faults or malfunctions

PROFIdrive is a standard for the communication of drive systems in industrial networks and ensures the integration of different drive types.

PROFIenergy combines energy management with automation. The profile helps to analyze and reduce energy consumption.

PROFIprocess ensures reliable transmission of process data and supports the automation of complex processes

Strategic partners

We are stack-neutral. This means that we are not tied to a specific manufacturer, but we can select the technologies best suited to your requirements. We are particularly familiar with the solutions of our strategic partners.

Through close cooperation with various manufacturers, we can select systems and components specifically according to their functionality, thereby optimally exploiting the advantages of modern Industrial Ethernet networks for your applications.

Your automation project in good hands

With us, you have the choice between different stacks. Each option optimally prepares you for future challenges such as PROFINET over TSN – the decisive factor is which solution best suits your requirements.

Functionality, security, and the advantage of continuous integration and automated testing are crucial for the success of Industry 4.0 projects and offer clear benefits for the efficient and secure implementation of modern automation solutions.

Throughout the entire process, we rely on continuous integration and automated testing with our Embedded System Integration Check Framework (ESIC).

Our aim is to offer you the highest level of functional reliability, adherence to deadlines and budget control. When it comes to consulting, we rely on our many years of experience in industrial communication.

Frequently asked questions about PROFINET

What are GSD files?

GSD files (General Station Description) are at the heart of the integration of PROFINET devices into a PROFINET network. They contain all relevant information about the properties, functions, and communication options of the respective PROFINET devices.

For users, this means:

The files can be used to integrate and configure new devices into the existing network. GSD technology is an essential part of the PROFINET architecture and ensures that the integration of new components runs smoothly and efficiently. With these files, the PROFINET network is scalable and can be expanded or modified even as requirements change.

H3: How important is PROFINET diagnostics?

Reliable PROFINET diagnostics are crucial for the trouble-free operation of your PROFINET networks. With modern diagnostic tools, users can monitor the status of all network participants, detect communication problems early on, and fix them in a targeted manner.

Diagnostics includes analyzing the network and then identifying and fixing errors. This is an important step in making sure your systems are available and performing well.

Effective PROFINET diagnostics and troubleshooting minimize downtime and ensure the long-term productivity of your systems.

For users, this means:

The files can be used to integrate and configure new devices into the existing network. GSD technology is an essential part of the PROFINET architecture and ensures that the integration of new components runs smoothly and efficiently. With these files, the PROFINET network is scalable and can be expanded or modified even as requirements change.

Is Ethernet the same as PROFINET?

Although Ethernet and PROFINET are closely related, they are not the same thing. Ethernet is a basic standard for data transmission in networks and is used in almost all areas of IT. It primarily defines how devices exchange different types of data in a local network.

PROFINET, on the other hand, is a communication protocol that was developed specifically for industrial applications. It is used in automation technology to connect controllers—such as programmable logic controllers (PLCs)—to sensors or other devices.

PROFINET uses the physical infrastructure of Ethernet, i.e., the same cables and switches, but differs fundamentally from Ethernet in the way it communicates.

Diagnostics includes analyzing the network and then identifying and fixing errors. This is an important step in making sure your systems are available and performing well.

Effective PROFINET diagnostics and troubleshooting minimize downtime and ensure the long-term productivity of your systems.

For users, this means:

The files can be used to integrate and configure new devices into the existing network. GSD technology is an essential part of the PROFINET architecture and ensures that the integration of new components runs smoothly and efficiently. With these files, the PROFINET network is scalable and can be expanded or modified even as requirements change.

What is the difference between PROFINET and IRT?

IRT (Isochronous Real Time) is an extended form of PROFINET that was developed for particularly demanding applications with very strict real-time requirements, such as those required in motion-synchronous drive applications, for example in robots, CNC machines, or packaging systems.

Unlike conventional PROFINET RT, IRT ensures that data transmission is precisely timed – and by that we mean accurate to the millisecond.

While PROFINET RT runs on standard switches and infrastructure, IRT requires specially designed hardware, such as IRT-enabled switches and devices with an integrated synchronization mechanism.

PROFINET, on the other hand, is a communication protocol that was developed specifically for industrial applications. It is used in automation technology to connect controllers—such as programmable logic controllers (PLCs)—to sensors or other devices.

PROFINET uses the physical infrastructure of Ethernet, i.e., the same cables and switches, but differs fundamentally from Ethernet in the way it communicates.

Diagnostics includes analyzing the network and then identifying and fixing errors. This is an important step in making sure your systems are available and performing well.

Effective PROFINET diagnostics and troubleshooting minimize downtime and ensure the long-term productivity of your systems.

For users, this means:

The files can be used to integrate and configure new devices into the existing network. GSD technology is an essential part of the PROFINET architecture and ensures that the integration of new components runs smoothly and efficiently. With these files, the PROFINET network is scalable and can be expanded or modified even as requirements change.

What is the difference between PROFIBUS and PROFINET?

PROFIBUS and PROFINET are both industry standards for communication in automation technology, but they're totally different in how they work and what they're used for.

PROFIBUS (Process Field Bus) is a serial fieldbus established since the 1990s that is based on RS-485 technology. It uses a master/slave communication principle and is particularly suitable for classic automation tasks such as controlling sensors and decentralized devices.

PROFINET (Process Field Network) hingegen basiert auf Ethernet-Technologie und wurde entwickelt, um den steigenden Anforderungen an Geschwindigkeit, Flexibilität und Integration in industrielle Netzwerke gerecht zu werden.

Unlike conventional PROFINET RT, IRT ensures that data transmission is precisely timed – and by that we mean accurate to the millisecond.

While PROFINET RT runs on standard switches and infrastructure, IRT requires specially designed hardware, such as IRT-enabled switches and devices with an integrated synchronization mechanism.

PROFINET, on the other hand, is a communication protocol that was developed specifically for industrial applications. It is used in automation technology to connect controllers—such as programmable logic controllers (PLCs)—to sensors or other devices.

PROFINET uses the physical infrastructure of Ethernet, i.e., the same cables and switches, but differs fundamentally from Ethernet in the way it communicates.

Diagnostics includes analyzing the network and then identifying and fixing errors. This is an important step in making sure your systems are available and performing well.

Effective PROFINET diagnostics and troubleshooting minimize downtime and ensure the long-term productivity of your systems.

For users, this means:

The files can be used to integrate and configure new devices into the existing network. GSD technology is an essential part of the PROFINET architecture and ensures that the integration of new components runs smoothly and efficiently. With these files, the PROFINET network is scalable and can be expanded or modified even as requirements change.

OUR SOFTWARE DEVELOPMENTS –

SELECTED EXAMPLES

We’ll be happy to provide you with insights into other projects any time. Just contact us!

Model-based software engineering for the vehicle control unit

GETTING THERE FASTER

We speed up the development and validation of vehicle control software using model-based software engineering.

DEVELOPMENT OF IOT AND EDGE APPLICATIONS

FOR SMART RAIL OPERATIONS

By monitoring “health states,” identifying optimization potentials in the network, and enabling predictive maintenance, our application development transforms your data into knowledge.

Subsystem integration for the vehicle control unit and operator network

SO IT ALL WORKS TOGETHER

When subsystem integration is performed for the vehicle control unit and operator network, we take full responsibility for combining multivendor architectures to form a functioning whole.

Innovations

WE’RE SHAPING THE FUTURE

We play an active role in both national and international research projects that are working to prepare rail vehicle technology for the challenges of future decades.

Development of a basic system

BASIS FOR THE FUTURE

By participating in international standardization projects, we’re contributing to the creation of a highly expandable and modular basic system of the future.

Device integration for SIMATIC PCS 7 / SIMATIC PCS neo

YOUR COMPONENTS IN A LEADING POSITION

Siemens’ SIMATIC PCS 7 and SIMATIC PCS neo control systems are leaders in the process industry. We take responsibility for a seamless, system-compliant integration of your products or third-party components.

PROFINET Stack Integration

WE HELP YOU MAKE IT TO THE BIG LEAGUES

You want to integrate PROFINET into your chips or devices – we handle the modification of the relevant stacks as part of a carefree package for you – right up to certification.

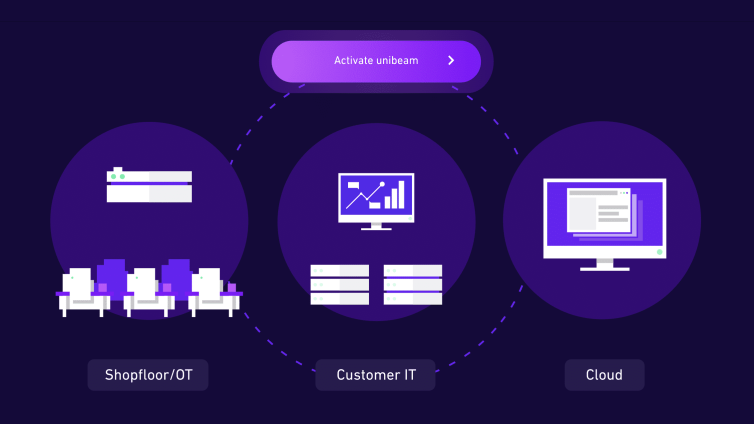

System integration for industrial communication

SO THAT NO DATA-POINT IS LOST

Whether it’s PROFINET, OPC UA, MQTT, or applications based on them, we take on the complete integration of products for industrial communication into your system environment.

Development of IoT and edge applications

DATA BECOMES THE BASIS FOR DECISION-MAKING

You want to turn big data into smart data. We’ll build your application – from data acquisition (connectivity) and data transmission to data evaluation and utilization.

IO-LINK LIBRARY FOR SIMATIC PCS 7/SIMATIC PCS NEO

Secure point-to-point connections in industry are relatively easy to implement with the right IO-Links. We offer you the right driver so that integration is in full compliance with the system.

TURCK Remote IO FOR SIMATIC PCS 7

The system-compliant connection of TURCK systems to the SIMATIC PCS 7 process control system doesn’t have to be time-consuming. Our function block library ensures maximum convenience at the user end.

unibeam. - And suddenly it's all Smart Factory.

Do you want to experience a new generation of IIoT-platforms? Discover unibeam: an amazingly simple and efficient software to help SMEs unfold their whole potential of digitalisation.

Cyber security for component manufacturers

SECURE FROM THE START

How we help you eliminate potential vulnerabilities in your products – from product development throughout the entire lifecycle.

Cyber security for plant operators:

MORE PROTECTION FOR YOUR ASSETS

How we can help you monitor and mitigate risks during operation – supported by our combination of system, software, and security expertise.